According to Momba et al., (2002) several

factors promote bacterial growth in drinking water distributions systems,

called regrowth, which occurs in the water phase and in biofilms on the pipe

surfaces and reservoirs. Different factors that affect regrowth in drinking

water distribution systems are as follows:

1. Temperature and pH

Temperature and pH are major factors that affect the

microbial growth by modifying the electrostatic interactions between surfaces

and microorganisms, enzymatic reactions, and many other properties e.g. diffusivity,

solubility. Microorganisms do withstand some variations in the pH as their own

metabolic activities alter the pH in the vicinity by producing acids. But

bacteria do have their optimum pH. Chen et

al., (2005) in his recent study concluded that attached Pseudomonas

fluorescens accumulated at a greater extent and more cohesively in the

biofilm at neutral pH than in other acid or basic media.

2. Disinfectant Agents

During transportation bacterial regrowth is

efficiently prevented by using chemical disinfectant and by maintaining the

residual in distribution system. However, regrowth do occur when residual decay

further down in the distribution system. Biofilm matrix along with EPS enclosed

the bacteria and protects from the disinfectants by preventing the penetration

of biocides, limiting the diffusion or by reacting. Lower concentration of

disinfectant concentration was found within the biofilm than in the water.

Besides, it actuated first in the outermost layer where as bacteria were found

to be metabolically active in the inner layers. Induction of stress responses

and development of biofilm-specific biocide resistant phenotype may contribute

to biocide resistance (Huang et al., 1995). Pathogenic bacteria hosted

inside the protozoa were also found to be one of the ways to increase the

resistance against biocides (LeChevallier et al., 1988)

3. Availability of

nutrients

Drinking water distribution systems is an

oligotrophic environment with low contents of carbon, nitrogen and phosphorous.

Several reports from the drinking water distribution systems in Australia

(Chandy and Angles, 2001), France (Servais et al., 2004), Singapore (Hu et

al., 2005), Netherlands (van der Kooij, 1992) and China (Bai et al.,

2006) observed that the organic carbon content was the limiting nutrient

because an increase in this nutrient promoted bacteria regrowth while in other

studies conducted in Japan (Sathasivan and Ohgaki, 1999) and Finland (Lehtola et

al., 2002) phosphorus had been found as limiting nutrient. Thus, nutrient

availability, impact on structure, sloughing rate of biomass, EPS production

and microbial adhesion of biofilm (Veiga et al., 1997).

4. Hydrodynamic

Conditions

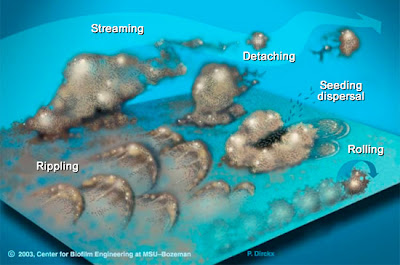

In drinking water distribution system, the hydrodynamic

conditions may ranges from laminar to turbulent flow, however stagnant

(no-flow) water also occurs in places where water consumption is low and in

reservoirs of buildings. The hydrodynamic condition may cause different effects

on biofilm accumulation and detachment. Increase in flow velocity initially

increases the nutrient transport rates until it reaches maximum and then

decreases with the further increase in flow velocity. Besides, the flow

velocity increases the biofilm density and detachment. It has been found from

previous research that hydrodynamic conditions and the nutrients are the two

major factors that influence biofilm growth, its structure, density and

thickness. Higher flow velocity have been found to increase cells hydrophobicity

that will favor cells aggregation and hence biofilm accumulation (Liu and Tay, 2001; Liu et al., 2003).

5. Surface Material

In drinking water distribution system, Iron-based,

cement-based materials and polymeric materials such as PVC (Polyvinyl chloride)

and PE (Polyethylene) are used in distribution network pipeline. In iron-based

pipeline materials, corrosion have been found as the major factor that

increases the soluble iron in the water, transport head loss and turbidity

(McNeill and Edwards, 2001).

There is still some controversy about the effect of

surface materials on biofilm development. Some researchers (Momba and Kaleni,

2002) demonstrated that drinking water biofilms grew less on polymeric

materials (PE, PVC, Teflon) than on iron

materials (grey iron, cast iron, galvanized steel, stainless steel, cemented

steel, asbestos-cement and cemented cast iron) however, opposite results were

found by other researchers (Cloete et al., 2003; Bachmann and Edyvean,

2005) where as in other works (Zacheus et al., 2000; Wingender and

Flemming, 2004) no significant difference was found.

Roughness, corrosion resistance, hydrophobicity and

hydrophilicity, Migrating components from surfaces and valves and

joints materials of the pipe materials used in drinking water distribution

system has been identified as an important factor affecting biofilm formation

(Pedersen, 1990). In a recent study it had been found pipe service age was an

important factor in the consumption of chlorine and this effect decreases in

the following order cast iron > steel > cement-lined cast iron =

cement-lined ductile iron > PVC = PE (Al-Jasser, 2007).

6. Protozoa Grazing

Protozoa are considered the major organisms

responsible for bacterial grazing in aquatic environments, which has been shown

to limit biofilm accumulation in drinking water systems (Berry et al.,

2006; Snelling et al., 2006). In contrast to predation, association of

several pathogenic bacteria to protozoa has been found as the latter have high

resistance to chlorine; hence promoting resistance against disinfectants and

increasing the health risk events.

No comments:

Post a Comment